Products

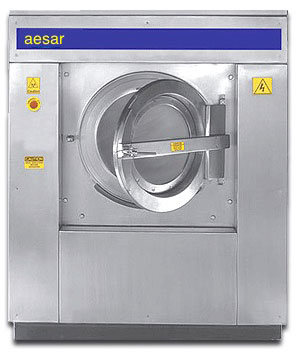

Side Loading Washing Machine - Model No. AISL - 21

Special Machine For

Enzyme/Denim Wash, Garment Washing, Milling Machine for Cotton & Woollen Sweaters Bath Mat Dyeing, For all Technical Washing, Pigment Dyeing of Knitted Garments All Laundry Jobs

Standard Features

Side loading washing machines is suitable or washing/milling of garments, cotton & woollen sweaters. Denim/enzyme wash, bath mats dyeing and dyeing of knitted garments. Inner & outer drum body is made with full stainless steel. Side plate is made in SGIN C.S & it is forming with anticorrosive material, it is 100% Corrosion proof (Swiss Made). A Special type of KRISTAL dimple made on the net of inner drum, which will not allow any chemicals there and because of that the used create similar & accurate pressure in the drum. The net of inner drum are made in parts, so at the time of any accident of breakage, can be replaced with that part only. Each & Every part of the model can be replaced separately because they are standard. Fully automatic electronic panel with INDUVASUL Cycle digital timer auto- reverse and forward drive with digital temperature controller & auto stop. Water level indicator through pilot lamp. Safety Features the machine stops automatically while opening the door through limit switch. All models are available in 3 phases or 1 phase as per order. We can also make new design machine as per your order & requirement. Unique design gives maximum O/P.

Aesar Make Heavy Duty Side Loading Washing Machine

| No. | Capacity k.g. |

Electric Motor |

Power Load |

Steam Connection Consumption |

Water Connection Consumption App. |

Inner Basket Size |

Main Door Frame |

Owerall Dimension |

Approx Weight |

| 1 | 15kg | 1hp | 4.5 kw | 0.5 bsp 15kg/hr | 1.0 bsp 30 lts/fill | 635 x 635 25 x 25 |

510 x 355 | 1550 x 680 x 1250 | 275 kg |

| 2 | 20kg | 1.5hp | 6.0 kw | 0.5 bsp 15kg/hr | 1.0 bsp 40 lts/fill | 760 x 915 30 x 36 |

510 x 355 | 1830 x 820 x 1320 | 300 kg |

| 3 | 30kg | 2hp | 9.0 kw | 0.5 bsp 20kg/hr | 1.0 bsp 50 lts/fill | 760 x 1220 30 x 48 |

610 x 460 | 1930 x 820 x 1320 | 400 kg |

| 4 | 50kg | 3hp | 14.0 kw | 1.0” bsp 40kg/hr | 1.0 bsp 100 lts/fill | 915 x 1220 36 x 48 |

610 x 510 | 2185 x 1250 x 1575 | 800 kg |

| 5 | 75kg | 5hp | 16.0 kw | 1.0” bsp 70kg/hr | 1.5 bsp 200 lts/fill | 915 x 1575 36 x 62 |

760 x 610 | 2490 x 1420 x 1600 | 1250 kg |

| 6 | 100kg | 7.5hp | 30.0 kw | 1.0” bsp 80kg/hr | 2.0 bsp 300 lts/fill | 1220 x 1525 48 x 60 |

865 x 610 | 2800 x 1675 x 1600 | 1800 kg |

| 7 | 150kg | 3hp 1 x 20 gb | 36.0 kw | 1.0” bsp 140kg/hr | 2.0 bsp 450 lts/fill | 1220 x 2030 48 x 80 |

865 x 610 | 3200 x 1780 x 1620 | 2250 kg |

| 8 | 200kg | 5hp 1x20 gb | 1.0” bsp 180kg/hr | 2.0 bsp 600 lts/fill | 1220 x 2550 48 x 100 |

760 x 510 2- d | 3500 x 1800 x 1620 | 2500 kg | |

| 9 | 400kg | 7.5hp 1x20 gb | 1.0” bsp 330kg/hr | 2.0 bsp 800 lts/fill | 1370 x 3900 54 x 154 |

760 x 510 2-d | 5990 x 1850 x 1620 | 3500 kg |

Side Loading Washing Machine

Side Loading Washing Machines that are known for its great washing and cleaning features. It is robustly constructed with the usage of high-grade raw materials. It is widely used in hotels, Dry-cleaning companies, and many others.

Features of Side Loading Washing Machines

- Electrically & mechanically interlocked, S.S.Loading & Unloading doors

- Drive: Heavy duty motor co-ordinates with gear box, Pulley V Belt drive

- Electrical Control: Well protected for performance auto timed, auto reverse & auto digital temperature control

- Protective device against single phasing, reverse phasing and motor overload

- Gauge glass cork pair for water level indication.

- Front display of controls through pilot lamps, push buttons, water level indication etc.

- Electric, Steam or thermal fluid heated

- Automatic features like auto timed, auto reverse, auto temperature controller with inching devise.

- Side Loading, open pocket, single & Double door, ideal for larger laundries

- Performs all Type of wash with soap, detergent, bleaching, acid, stone or any chemical wash including dying

- Ideally suited for Denim/Stone Washing, Enzyme Washing, Garment Dying & Bleaching, Softening, Milling Operation (for woolens)

- Interlocking system for main door opening for extra safety.

Tumble Dryer - Front Loading - Model No. AITD - 61

- The tumble driers use the 01 heat exchange to dry garments and other articles that have just been washed.

- The complete stainless steel (AISI Grade 304) basket that holds the articles Is precision punched In a CNC machine and is supported by sell aligning ball bearing lower a noiseless operation. The sizes 01 the perorations 01 the inner basket are optimally designed so as to ensure the right amount of air flow. The inner basket has stainless steel paddles also manufactured in a CNC machine to ensure consistency in the lifting of garments.

- The outer body is completely powder coated in our In house powder coating facility to ensure a long life.

- An individual micro controls based control system come with this machine. Settings than are displayed and can be programmed include cycle times.

- Digital temperature control And Tow Way Swatch.

- Individual Micro Control Auto Timed, Auto- Reserve & Forward time.

- The heat exchange can be powered with steam, & Electrical Heated.

- A reversing inner basket to prevent garments from tangling and a large door opening for ease of loading and unloading articles come standard.

- Emergency stop buttons and a safety limit switch is pre installed to ensure safety of the operator.

- The lint filter is extremely large and very easy to clean (low The inner basket is doubly insulated with the finest quality mineral wool held in place by aluminium sheets on loaded spring hooked ties.

Aesar Hydro Extractor Direct Drive

| Capacity (kgs) |

Basket Size mm/inch |

Drive Motor hp |

Blower Motor |

Steam Connection & Consumption |

Air Outlet (mm) |

Electric Heating (kw) |

Main Door Opening |

Dimensions ( W x D x H) |

Net Weight (kgs) |

| 15 | 760 x 600 30 x 24 |

0.5 | 0.5 | 15mm BSP 20 kg/Hr | 250 x 250 mm | 9 to 12 | 450mm | 650 x 1150 x 1700 | 375 |

| 30 | 915 x 915 36 x 36 |

1 | 1 | 15mm BSP 35kg/Hr | 300 x 300 Mm | 16 x 20 | 600 mm | 1100 x 1350 x 1800 | 450 |

| 60 | 1180 x 990 46 x 49 |

2 | 1.5 | 25mm BSP 50 kg/Hr | 350 x 350 Mm | 24 to 30 | 775mm | 1350 x 1825 x 2300 | 670 |

| 100 | 1680 x 1120 66 X 44 |

3 | 1.5+1.5 | 25mm BSP 90 kg/Hr | 400 x 400 Mm | N/A | 850 mm | 1900 x 2210 x 2700 | 900 |

| 120 | 1830 x 1270 72 x 50 |

3 | 2+2 | 38mm BSP 120 kg/Hr | 400 x 400 mm | N/A | 1050 | 2200 x 2600 x 3100 | 1100 |

Hydro Extractor Direct Drive - Model No. AIHE – 51DD

Aesar Hydro Extractor Machine Direct Motor Drive, self- Balancing. This machine has good excellent performance like low noise and vibration free due to its unique Suspension system. It takes less time due to its high speed rotation having good results with Automatic Electromagnetic DC Injection Brake System Having Capacity of 15 to 50 Kg. per charge with Auto-Timed, Top Loading Vibration Less, Inner Basket And Outer Drum Stainless Steel With specially designed foundation frame for grouting the machine having the facility of dismantling the inner basket without dismantling the outer body, complete with specially Designed Electric Motor and Digital Control Panel.

Aesar Hydro Extractor Direct Drive

| Capacity kegs | 15Kgs | 25Kgs | 30Kgs | 50Kgs |

| Cylinder size mm | 510 x 300 | 610 x 350 | 710 x 350 | 915 x 400 |

| Cylinder size inch | 20” x 12” | 24” x 14” | 28” x 14” | 36” x 16” |

| Extractor motor | 2HP | 3HP | 5HP | 7.5HP |

| Cylinder speed | 960rpm | 960rpm | 960rpm | 900rpm |

| Drain DIA | 50MM | 50MM | 75MM | 100MM |

| App weight | 250Kg | 350Kg | 450Kg | 750Kg |

| Overall Dimension W x D x H |

760 x 1010 x 1100 | 1000 x 950 x 1100 | 1150 x 950 x 1200 | 1300 x 1100 x 1250 |

Hydro Extractor Three Suspensions - Model No. AIHE – 51TS

Aesar Hydro Extractor Three Suspensions inner outer drum body is made from Stainless Steel Specially Designed Three Leg Spring Mounted Sus-pensions. High Speed Heavy Gamete NTN Bearing Housing, 100% Spare Replacement. Each & Every part of the model can be replaced instant because they are standard. All models are available in 3 phases as per order we can also make new design machine.

As per your customer Requirement O/P variables Speed drives & Different Capacity Machine are also possible.

Aesar Hydro Extractor Three Suspensions

| Capacity kegs | 20Kgs | 30Kgs | 40Kgs | 50Kgs |

| Cylinder size mm | 450 x 350 | 600 x 350 | 750 x 400 | 900 x 400 |

| Cylinder size inch | 18” x 14” | 24” x 14” | 30” x 16” | 36” x 16” |

| Extractor motor | 1HP | 1.5HP | 2.5HP | 3.5HP |

| Cylinder speed | 1500rpm | 1350rpm | 1000rpm | 900rpm |

| Drain DIA | 1.5”flinch type | 1.5”flinch type | 2”flinch type | 2”flinch type |

| App weight | 325Kg | 465Kg | 650Kg | 1100Kg |

The Company reserves all the rights to alter specifications and design without prior notice for further improvements.

Front Loading Washing & Processing Machine - MODEL NO. AIFL - 31

Standard Feares

Industrial Washing Machine Frontloading, Open Pocket with or without low spin Extract; Frontloading machines are technically very efficient for all kinds of laundry / dyeing process, In these machines liduor ratio is almost half the reduired in side loading machines, The body of the machine is fabricated out of stainless steel. Every joint is welded with argon welding.

The inner drum basket is made of perforated S.S sheet shaving smooth, fine joint, Complete stainless steel front & inner outer clinder, inner basket and outer drum all highly polished stain less steel. Easy Loading & unloading through large tough ended glass door. Electrical Control Well protected For Performance Digital individual cycle Auto reveres& forward timer set of different type linen Auto Digital temperature control. The Machine stop automatically on opening the door Easy to Operate & Space Saving. Electric or Steam Heated Type.

Aesar Front Loading Washing Machine

| CapacityDry Wt. Per Charge |

Basket Size Volume |

Wash Motor & Wash Speed |

Main Door Size |

Water Connection & Consumption App |

Drain | Steam Consumption |

Electric Load |

Overall Dimensions W x D x H |

App Weight |

| 15 Kg. | 810 X 410 (32.4” x 16.4”) 211 Lts. |

0.75 Kw 35 RPM |

500 mm | 1.0” BSP *100 Lts FILL |

2” | 0.5” BSP 15Kg/Hr |

6 Kw | 950 x 1015 x 1500 | 550 Kg |

| 25 Kg. | 960 x 500 (38.4” x 20”) 362 Lts. |

0.75 Kw 35 RPM |

500 mm | 1.0” BSP *100 Lts FILL |

3” | 0.5” BSP 25Kg/Hr |

12 Kw | 1120 x 1450 x 1750 | 840 Kg |

| 50 Kg. | 1110 x 760 (44.4” x 30.4”) 735 Lts. |

1.5 Kw 35 RPM |

650 mm | 1.5” BSP *250 Lts FILL |

3” | 0.5” BSP 50Kg/Hr |

24 Kw | 1240 x 800 x 1900 | 1350 Kg |

| 75 Kg. | 1200 x 850 (48” x 34”) 1230 Lts. |

2.0 kw 35 RPM |

750 mm | 1.5” BSP *325 Lts FILL |

3” | 0.5” BSP 75Kg/Hr |

30 Kw | 1440 x 1000 x 2100 | 1450 Kg |

| 100 Kg. | 1360 x 990 (54.4” x 16.4”) 1437 Lts. |

3.75 Kw 25 RPM |

800 mm | 2.0” BSP *500 Lts FILL |

4” | 0.5” BSP 100Kg/Hr |

36 Kw | 1520 x 1200 x 2100 | 1750 Kg |

Washer Extractor - MODEL NO. AIWE - 41

Procuct Description

Aesar series automatic-fully washer extractor

- Automatic –fully washing and extracting machine, drum and body all made of 304 stainless steel and easy to operate and it does the washing and extracting functions together.

- Steam or electrical heating.

- Its capacity is from 10Kg to 160Kg.

- Programmable computer control system, it is highly automatic, safe, stability and shock proof.

- We adopt the latest international complete suspension structure to reduce shock, replace the original shock design by liquid pressure buffer with springs, to ensure an ideal shock proof effect even on higher floors.

- It is with a drum without compartment and single door structure convenient to loading orunloading, and reduces the labour intensity and improves the clean level.

- With fully-closed and rear-drainage structure, it is good for environment protection; the drum and case are both made of high quality IS 304 stainless steel with the advantages of stain resistance and durability.

- The new micro- computer control washer-extractors offer our customers with easy programming, and tremendous energy savings compared. Owners will be impressed with the water savings they achieve and the benefits to their operation. The easy-to-use controls and flexibility of the pre-programmed cycles will be a hit with customers. They can add an extra wash, rinse or choose both to create a personalized wash cycle based on their individual needs. Customers will appreciate the large LED display that leads the user through the washing process.

- The automatic-fully washer extractor are usually used for hotel, restaurant, school, hospital, counter pane factory and laundry house, etc.

Aesar Front Loading Washing Machine

| Capacity Per Charge KG |

Basket Size in mm volume |

Drive Motor |

Wash RPM |

Final Extract RPM |

Door Opening in mm |

Water Connection |

Drain | Steam Conne Consumption |

Electric | Dimensions | Net Wt Shipping Wt |

| 10 | 550 x 350 | 1.5 HP | 35 to 45 | 900 | 400 | 0.25mm Electrical | 0.50 mm Electrical | 0.15mm 10Kg H/R | 4 Kw | W660 D760 H1100 | 250 Kg/ 290Kg |

| 15 | 790 x 300 | 3.0 HP | 35 to 45 | 900 | 450 | 0.25 mm Electrical | 0.50 mm Electrical | 0.15mm 15Kg H/R | 6 Kw | W1050 D1080 H1575 | 540 Kg/ 525Kg |

| 20 | 900 x 300 | 3.0 HP | 35 to 45 | 800 | 500 | 0.25 mm Electrical | 0.50 mm Electrical | 0.15mm 20Kg H/R | 8Kw | W1060 D1450 H1600 | 1000 Kg/ 1100Kg |

| 30 | 900 x 500 | 7.5 HP | 35 to 45 | 800 | 550 | 0.38 mm Pneumatic | 0.75 mm Pneumatic | 0.15mm 30Kg H/R | 16Kw | W1350 D1450 H1725 | 1200 Kg/ 1350Kg |

| 60 | 1100 x 650 | 12 HP | 35 to 45 | 750 | 650 | 0.38 mm Pneumatic | 0.75 mm Pneumatic | 0.15mm 60Kg H/R | 22kw | W1700 D1800 H2025 | 2200 Kg/ 2450Kg |

| 100 | 1300 x 790 | 20 HP | 35 to 45 | 700 | 700 | 0.50 mm Pneumatic | 100 mm Pneumatic | 0.25mm 90Kg H/R | N/A | W1950 D2110 H2300 | 3800 Kg/ 4100kg |

| 120 | 1350 x 850 | 25 HP | 35 to 45 | 700 | 850 | 0.50 mm Pneumatic | 100 mm Pneumatic | 0.25mm 120Kg H/R | N/A | W2050 D2250 H2400 | 4400 Kg/ 4900kg |

| 160 | 1460x 950 | 35 HP | 35 to 45 | 700 | 950 | 0.50mmx2Nos Pneumatic |

100mmx2Nos Pneumatic |

0.38mm 150Kg H/R | N/A | W2350 D2400 H2500 | 5500 Kg / 6000Kg |